The Fourth Industrial Revolution (4IR) is characterized by the transformative integration of edge computing and AI, significantly impacting industrial automation. Edge computing enhances efficiency by processing data closer to its source, reducing latency. Paired with AI, it enables real-time monitoring, predictive maintenance, and process optimization in industrial environments. This combination is key to the ongoing transformation in Industry 4.0, setting new standards in a digitized, data-driven world.

In an era where Industry 4.0 is the frontier, the synergy of AI and edge computing is paving the way for unprecedented advancements in industrial automation. These groundbreaking technologies are not merely buzzwords, but critical components in the transformation of industries worldwide. This article explores the compelling role of edge computing in shaping Industry 4.0, leveraging AI to pioneer real-time monitoring, and facilitating advanced control of industrial processes.

In the first section, we delve into the power of edge computing in spearheading the 4IR transformation. Here, we unravel how edge computing is the catalyst, driving the evolution of traditional industries into smart, self-regulating behemoths of efficiency and productivity.

Next, we explore the dynamic partnership between AI and edge computing. This union is at the heart of real-time monitoring in industrial automation, leading the charge in making factories smarter and more responsive than ever before.

Finally, we examine the 4IR revolution and how edge computing is facilitating advanced control of industrial processes. We look at the practical applications and tangible benefits that this technology is bringing to the table, from streamlining operations to boosting bottom lines.

As we navigate through these sections, one thing becomes clear: edge computing is not just a trend—it is a transformative force, shaping the future of industrial automation. Buckle up as we take a deep dive into this fascinating world, where technology, innovation, and industry converge in a spectacular display of 4IR prowess.

- 1. "Harnessing the Power of Edge Computing in Industry 4.0 Transformation"

- 2. "AI and Edge Computing: Pioneering Real-Time Monitoring in Industrial Automation"

- 3. "The 4IR Revolution: Edge-Computing Facilitating Advanced Control of Industrial Processes"

1. "Harnessing the Power of Edge Computing in Industry 4.0 Transformation"

Industrial transformation, also known as the Fourth Industrial Revolution (4IR), is not a mere trend, but a reality that's swiftly reshaping the way we manufacture, process, and distribute goods. At the heart of this transformation lies a powerful duo: edge computing and artificial intelligence (AI).

Edge computing, in its simplest form, is the concept of bringing computation and data storage closer to the source of data. This approach minimizes latency, accelerates response times, and allows for real-time decision-making. It is a game-changer for industries, particularly in the context of Industry 4.0.

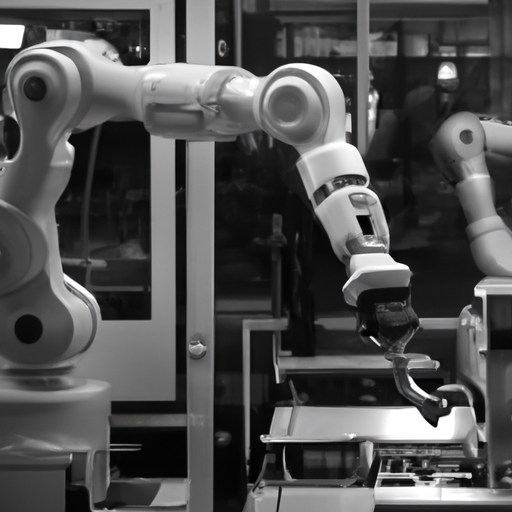

The role of edge computing is pivotal in Industrial Automation. It offers a promising solution to address the growing need for real-time monitoring, control, and optimization of industrial processes. For instance, in a manufacturing plant, edge devices can collect, process, and analyze data from thousands of sensors distributed across the plant. This data could pertain to machine performance, product quality, or even environmental conditions.

By harnessing the power of edge computing, companies can minimize downtime, optimize resource allocation, and boost overall productivity. With the ability to process data on site, without the need for transmission to a remote server, edge computing offers a level of speed and efficiency that is simply unattainable with traditional cloud-based systems.

Meanwhile, AI plays a complementary role. It brings the 'intelligence' to edge computing, enabling machines to learn from data, identify patterns, make decisions, and even predict future trends. AI algorithms can continuously monitor operational data, detecting anomalies that could signify a potential equipment failure, process inefficiency, or quality issue. This allows for proactive measures, preventing costly downtime and improving process efficiency.

To sum up, edge computing and AI are crucial components of the 4IR transformation. By combining real-time data processing with AI-driven insights, they pave the way for a new era of Industrial Automation – an era that is smarter, faster, and more efficient than ever before. The power of edge computing, when harnessed appropriately, can help industries thrive in the face of rising competition and ever-increasing customer demands.

2. "AI and Edge Computing: Pioneering Real-Time Monitoring in Industrial Automation"

In the dynamic landscape of Industry 4.0, the Fourth Industrial Revolution (4IR), artificial intelligence (AI) and edge computing are emerging as transformative forces. They are not merely buzzwords but pivotal elements shaping the future of industrial automation.

Edge computing, in a nutshell, is a distributed computing paradigm that brings computation and data storage closer to the location where it's needed, thereby enhancing response times and saving bandwidth. With the integration of AI, edge computing offers an efficient solution for real-time monitoring in industrial automation.

How does this work? Picture a manufacturing plant bustling with activity. On the plant floor, high-tech machines, sensors, and systems are interconnected, generating a constant stream of data. Traditionally, this data would be sent to a centralized cloud platform for processing, which could lead to latency issues and bandwidth congestion.

Enter edge computing. By processing data on the edge of the network – close to where it's generated – we can avoid many of these issues. This, in turn, facilitates real-time monitoring and control of industrial processes. It's like having a local intelligence on-site, making quick decisions and taking immediate actions, thus ensuring smoother, more efficient operations.

AI enhances this process by adding a layer of cognitive intelligence. Imagine a system that not only collects and analyzes data but also learns from it. AI algorithms can detect patterns and anomalies, predict failures, and optimize operations, all in real-time. This AI-driven edge computing model is revolutionizing industrial automation, enabling unprecedented levels of productivity, efficiency, and cost savings.

Moreover, AI and edge computing together are pioneering predictive maintenance, a crucial aspect of Industry 4.0. Instead of following a set maintenance schedule, machines can now communicate when they need repairs or replacements. This not only minimizes operational disruptions but also extends the life of machinery and reduces costs.

In the age of 4IR, this transformative synergy of AI and edge computing is reshaping the industrial landscape. It is empowering industries to adapt, innovate, and thrive in an increasingly digital, data-driven world. By harnessing the power of these technologies, we can unlock the full potential of industrial automation and set the stage for a more resilient, sustainable, and productive future.

3. "The 4IR Revolution: Edge-Computing Facilitating Advanced Control of Industrial Processes"

In the heart of the 4th Industrial Revolution (4IR), a transformational shift is occurring; Edge Computing is steadily becoming a critical component in the realm of industrial automation. With its ability to facilitate real-time monitoring and control of industrial processes, edge computing is proving to be a game-changer in the industrial sector.

Edge computing brings computation and data storage closer to the devices where it's being gathered, rather than relying on a central location that can be hundreds of miles away. This means that industrial systems can process data on-site, in real-time, reducing latency and enhancing efficiency. The practical implications of this are vast, enabling industries to operate at levels of precision and speed previously unattainable.

The implementation of edge computing in automation is not just about speed and efficiency. It's about harnessing the power of data in unprecedented ways. By processing data on the edge, industries can leverage Artificial Intelligence (AI) to make smarter, faster decisions. AI, combined with edge computing, provides a powerful tool for predictive maintenance, quality control, and process optimization.

Predictive maintenance, for example, becomes a reality with edge computing and AI working in tandem. Sensors can monitor equipment health in real-time, AI algorithms can analyze this data on the edge, predicting potential failures before they occur. This proactive approach can save industries valuable time, money, and significantly enhance operational uptime.

In quality control, AI can analyze data from video feeds, sensors, and other sources in real-time, identifying anomalies and defects that might be missed by human inspection. This ensures not only superior quality but also faster identification and rectification of issues, minimizing wastage and enhancing productivity.

Process optimization is another area where edge computing is making significant inroads. Real-time data analysis allows for immediate adjustments to processes, enhancing efficiency, and reducing waste. AI can analyze complex data patterns, identifying areas of inefficiency, and suggesting improvements.

In essence, edge computing is not just facilitating but spearheading the transformation in industrial processes in the era of 4IR. By bringing data processing to the edge, industries can unlock the full potential of AI, driving efficiency, innovation, and growth. This is not the future of industrial automation. It's happening now, and the dividends are already being seen. The 4IR revolution, driven by edge computing, is here, and it's transforming the industrial landscape in ways that were previously unimaginable.

In conclusion, it is clear that edge computing is not just a futuristic concept; it's a reality that is revolutionizing industrial automation today. The transformation in Industry 4.0, powered by edge computing, has unveiled a new era of efficiency and productivity.

The fusion of AI and edge computing has pioneered a paradigm shift, giving birth to real-time monitoring in industrial automation. This combination of technologies has streamlined the process of data acquisition and analysis, improving predictive maintenance and minimizing the risk of system failures.

Furthermore, the 4IR revolution is being propelled by advanced edge-computing solutions, facilitating precise control of industrial processes. The ability to process and analyze data on the edge, closer to the source, is providing a competitive edge, reducing operational costs and improving overall system performance.

In essence, the impact of edge computing on industrial automation is profound and far-reaching. As we continue to navigate the 4IR transformation, it's clear that the future of industry lies in harnessing the full potential of edge computing and AI technologies. The possibilities are boundless, and the journey has only just begun.